Mastering Aluminum Cases with Foams Production

In the rapidly evolving landscape of packaging and protection, aluminum cases with foams production stand out as a versatile solution for various industries. At MSAcase, we specialize in the design and manufacture of top-of-the-line aluminum cases optimized with foam interiors for safeguarding valuable equipment and instruments. This article dives deep into the intricate world of aluminum case manufacturing, exploring their benefits, customization options, and the critical role they play in a myriad of applications.

Why Choose Aluminum Cases?

Aluminum cases are increasingly favored for their remarkable properties. Here are some compelling reasons to consider aluminum cases:

- Durability: Aluminum is inherently strong yet lightweight, making it an ideal choice for both protection and portability.

- Corrosion Resistance: Unlike other materials, aluminum is resistant to rust and oxidation, ensuring the longevity of the case.

- Security: Aluminum cases can be secured with locks or latches, offering protection against unauthorized access.

- Customizability: Aluminum cases can be tailored in size, shape, and finish to meet specific requirements.

Understanding Foams in Aluminum Cases

The inclusion of foam in aluminum cases significantly enhances their protective capabilities. Foams act as shock absorbers, safeguarding sensitive equipment from impact during transport. At MSAcase, we utilize advanced foam materials such as:

- EVA Foam (Ethylene Vinyl Acetate): Known for its elasticity and stress-crack resistance, making it an excellent cushioning material.

- Polyurethane Foam: Offers superior shock absorption and can be custom-cut to fit specific tools or devices.

- Closed-Cell Foam: Resistant to moisture and chemicals, providing an extra layer of protection for delicate items.

Custom Aluminum Case Solutions

One of the standout features of MSAcase is our ability to provide custom solutions tailored to the unique needs of our clients. Custom aluminum cases can be designed for a myriad of applications including:

1. Medical Equipment Transport

Medical professionals require reliable storage and transportation solutions for sensitive equipment. Our aluminum cases with foams production ensures instruments such as surgical tools and diagnostic devices are securely housed and protected from external damage.

2. Electronics and Technology

For businesses in the tech sector, protecting sophisticated electronics is paramount. We offer custom foam inserts that cradle devices while minimizing movement, thus preventing damage during transit.

3. Military and Defense Applications

Our aluminum cases are designed to meet stringent military specifications. With robust construction and the ability to withstand extreme conditions, these cases serve as ideal transport solutions for essential equipment in defense operations.

Benefits of Utilizing MSAcase for Aluminum Cases with Foams Production

When partnering with MSAcase for your aluminum case needs, you can expect:

- Expert Consultation: Our team of experts offers guidance from concept to delivery, ensuring you receive the right solution for your needs.

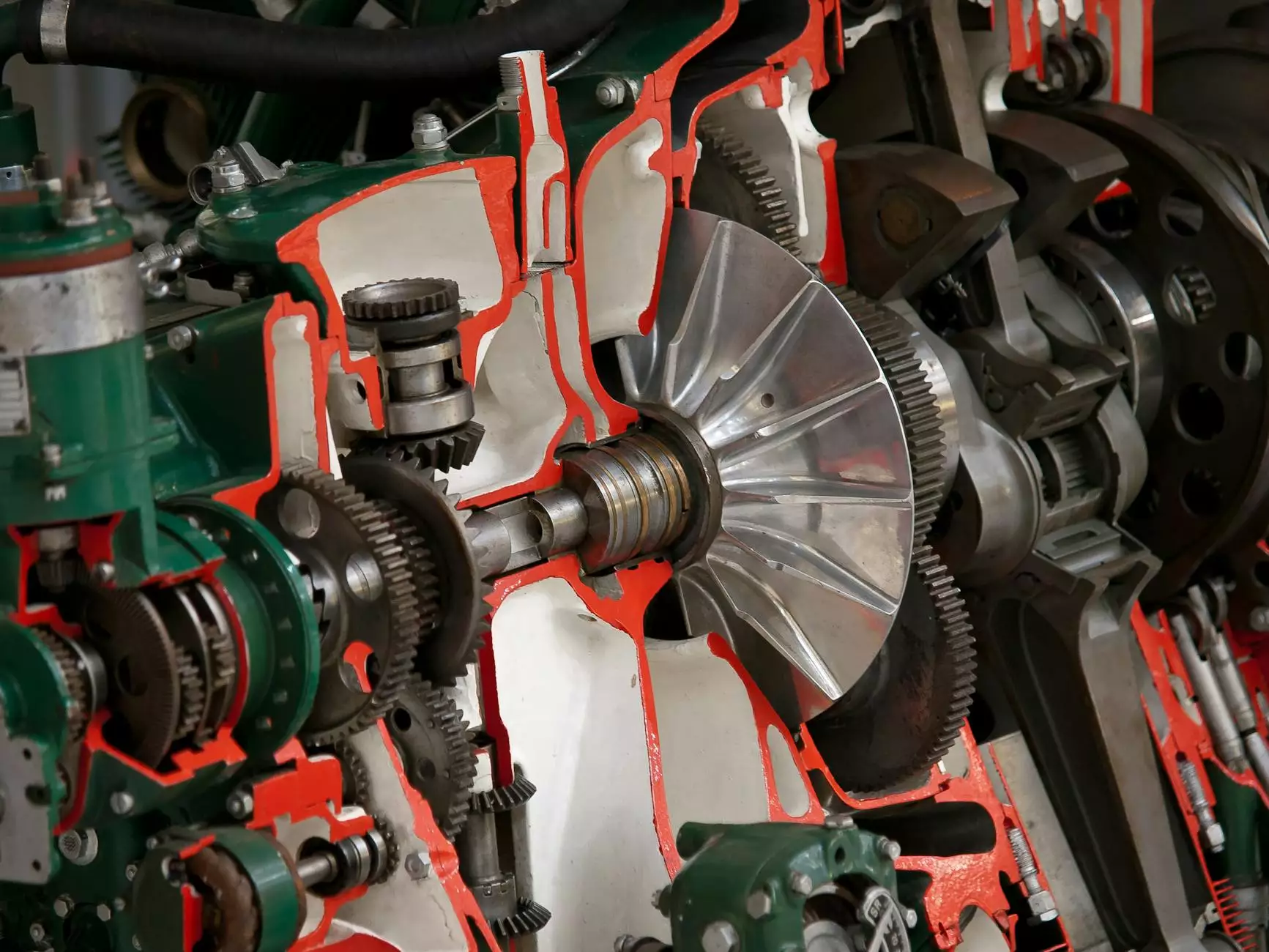

- State-of-the-Art Manufacturing: We employ advanced manufacturing techniques and equipment to produce high-quality cases that stand the test of time.

- Quality Assurance: Each case undergoes rigorous testing to ensure it meets our high standards for quality and durability.

- Competitive Pricing: We provide high-quality cases at competitive prices, ensuring value for every investment.

The Manufacturing Process of Aluminum Cases

The production of aluminum cases involves several carefully coordinated steps:

1. Material Selection

We source high-grade aluminum sheets and foam materials to ensure every case is robust and reliable.

2. Cutting and Shaping

Using ultra-precise cutting tools, we shape the aluminum to fit the specific requirements of each case design.

3. Foam Integration

The chosen foam materials are then cut to fit perfectly inside the aluminum shell, creating an optimal cushioning system.

4. Assembly

Each component is carefully assembled, ensuring that every case maintains its structural integrity and functionality.

5. Quality Control

Before dispatch, all cases undergo thorough quality checks to ensure they meet the highest standards.

Common Applications of Aluminum Cases with Foams Production

Aluminum cases are versatile and applicable across various industries. Here are some common applications:

- Photography Gear: Photographers require durable cases to protect their cameras and lenses during travel.

- Tools and Equipment: Customized cases provide organized storage for tools, ensuring they remain secure and accessible.

- Sports Equipment: Athletes use aluminum cases to transport equipment safely, ensuring it stays in top condition.

- Science and Education: Educational institutions use these cases to securely transport scientific instruments and lab equipment.

Eco-Friendly Practices at MSAcase

At MSAcase, we recognize the importance of sustainability. Our manufacturing process incorporates eco-friendly practices:

- Recyclable Materials: We source recyclable aluminum and foam materials, reducing our environmental footprint.

- Efficient Manufacturing: Our methods minimize waste and energy consumption throughout the production stage.

- Long-Lasting Products: By creating durable solutions, we contribute to reducing the need for replacements and excessive waste.

Customer Success Stories

Our commitment to excellence has fostered lasting relationships with customers across multiple sectors. Here are a few success stories:

1. Medical Facility Case Study

A local medical facility approached us to design custom cases for their surgical instruments. After consultations, we provided cases that met their stringent requirements, significantly improving their equipment transportation.

2. Tech Company Case Study

A tech startup needed specialized cases for their sensitive electronic prototypes. Our tailored solutions ensured that their devices were protected from shock and vibration during transportation, leading to enhanced product reliability.

Conclusion: Invest in Quality with MSAcase

As we have explored throughout this article, the production of aluminum cases with foams offers unparalleled benefits for protection, customization, and versatility. With MSAcase, you are guaranteed to receive expert guidance, superior quality manufacturing, and solutions suited to meet your specific needs.

If you are looking for a trusted partner in aluminum case manufacturing, reach out to MSAcase today. Your satisfaction is our priority, and we look forward to providing you with the best in aluminum case solutions.